How To Braze Stainless Steel

Wholesale Stainless Steel Brazing Welding Rods Supplier In Mumbai India

www.dwarkametalcorporation.com

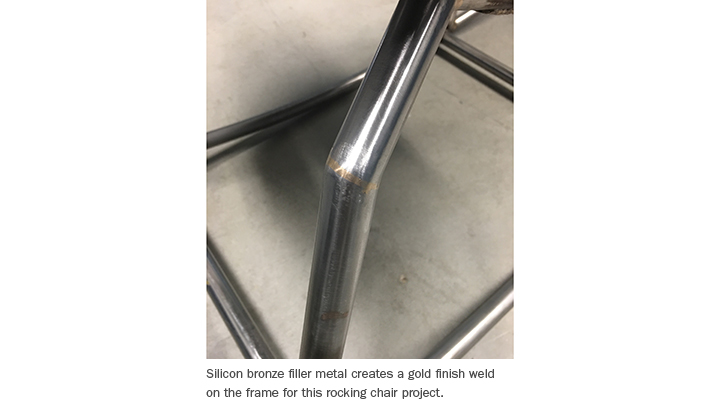

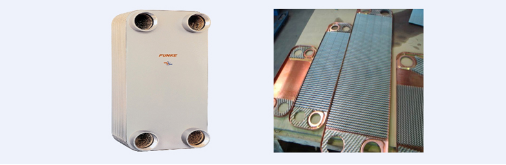

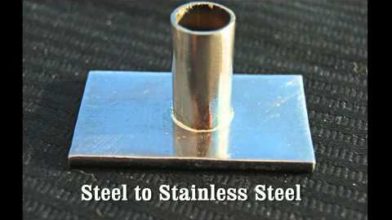

In particular it is advantageous for joining dissimilar materials that cannot be welded together.

.gif)

How to braze stainless steel. Brazing stainless steel is considered easy to perform if a basic understanding of the materials is obtained and if the applicable processes are mastered. Wipe the stainless steel down with a solvent to remove oil and grease. Brazing stainless steels requires adequate planning as the alloys used to form joints must have properties compatible with the base metal.

Follow these 5 steps on how to braze metal like a professional. Pre treating the stainless steel 1. Apply flux to both surfaces to be brazed make sure you have a flux that is capable of etching stainless steel.

Work in a well ventilated area and wear protective equipment. Steps use the wire brush or emery cloth to scuff the surface of the metal. Tune in for todays tips on torch brazing stainless steel.

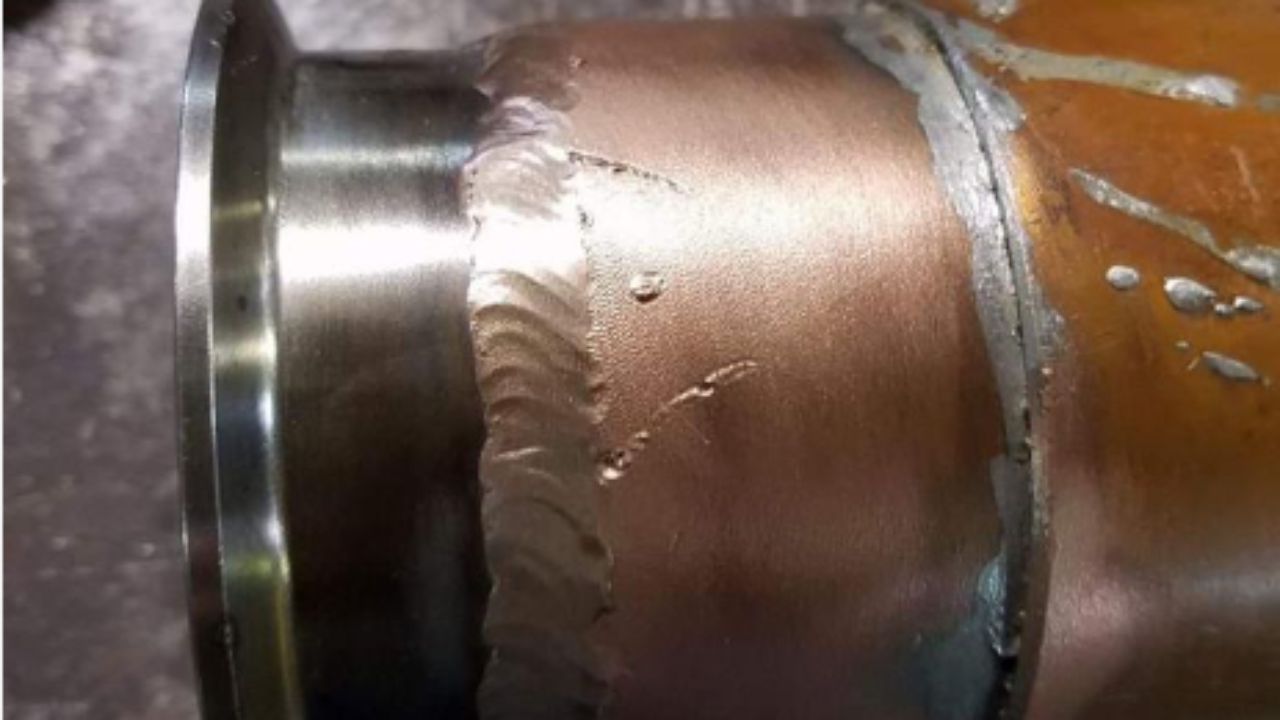

Then clean the surfaces using soapy water or a. However a key advantage is that many dissimilar metals can be joined to stainless steels by brazing. When properly applied brazing stainless permits to build strong and leak tight joints in thin wall items with minimum deformation.

Now position the metal properly. Then clean the surfaces using a degreaser or soapy water. Position the metal as desired.

Apply emery cloth or wire brush to scrape the metal surface. Surface contaminants prevent soldered material. Soldering stainless steel requires solvents and other.

Clean the surface with steel wool or an emory cloth. Slip parts together and start heating the copper in a circular motion making sure to heat.

Soldering Brass To Stainless Steel With Ssf 6 56 Silver Solder And A Propane Torch Youtube

www.youtube.com

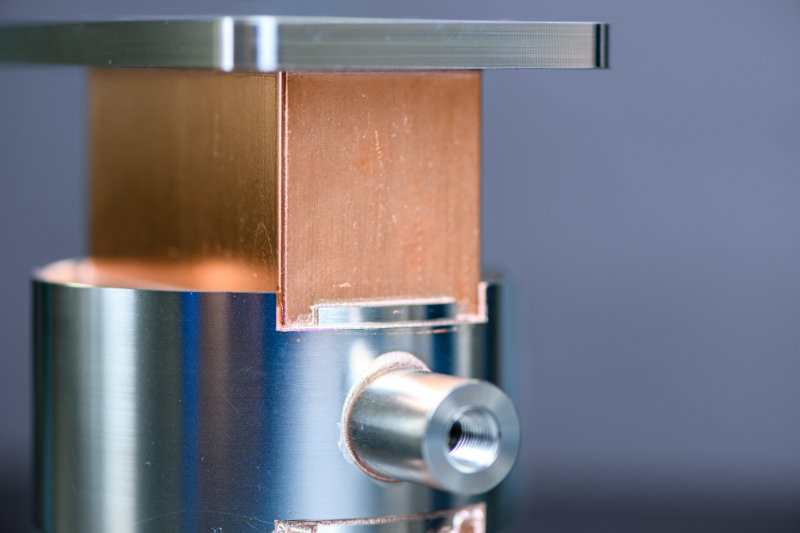

Ultraflex Brazing Stainless Steel To Copper Using Induction Heating Ultraflex Power Technologies Prlog

www.prlog.org

.jpg)