How To Cerakote A Gun

Cerakote on the other hand thrives around half that application 1 mil.

How to cerakote a gun. This high speed video shows the entire process of coating a firearm in one of our. Cerakote is a durable firearm finish that not only protects from rust and corrosion it also is vary slick. A similar market product powder coating must be applied at a minimum of 21000 2 mil.

Cerakote is ridiculously thin. Cerakote is a professionally applied oem finish it is not a diy finish. The increased ease of use and ability to precisely monitor curing temperatures make it a solid winner.

Weve received quite a few questions recently about our cerakote technique. But of course simple doesnt mean easy. We started out with a improvised oven which was nothing more then an old sheet metal gun safe with a heat gun and recently graduated to the brownells bake on finish curing oven.

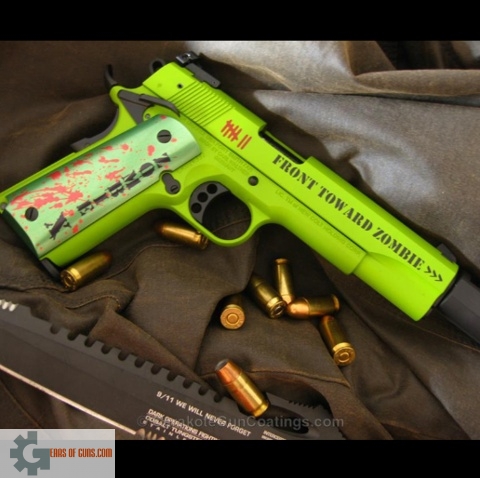

Gun with cerakote finish by lionheart industries gunbelt by bigfoot gunbelts iwb holster by alien gear holsters cerakote finish is a type of durable gun coating. Nic industries offers the only one on one training program for cerakote in north america. Disassembly sandblasting cleaning painting and baking.

All parts that will be. In this video we will show you the process that y. Cerakote application process your firearm is received in our shop and examined to make sure it is in safe working order.

In step 2 the firearm is completely disassembled every last pin nut screw and spring if the weapon has a barrel. Once it is determined that. You will receive individual training at our state of the art facilities in white city oregon.

-1024x1024.jpg)